Process Control

Since Reclaimed Rubber is made from end-of-life waste rubber, the final product is as consistent as the feedstock used to produce it. To ensure this consistency, AR has a nation-wide spread network of suppliers that are trained to sort and separate the prescribed type of scrap that is used to produce the high-quality end products.

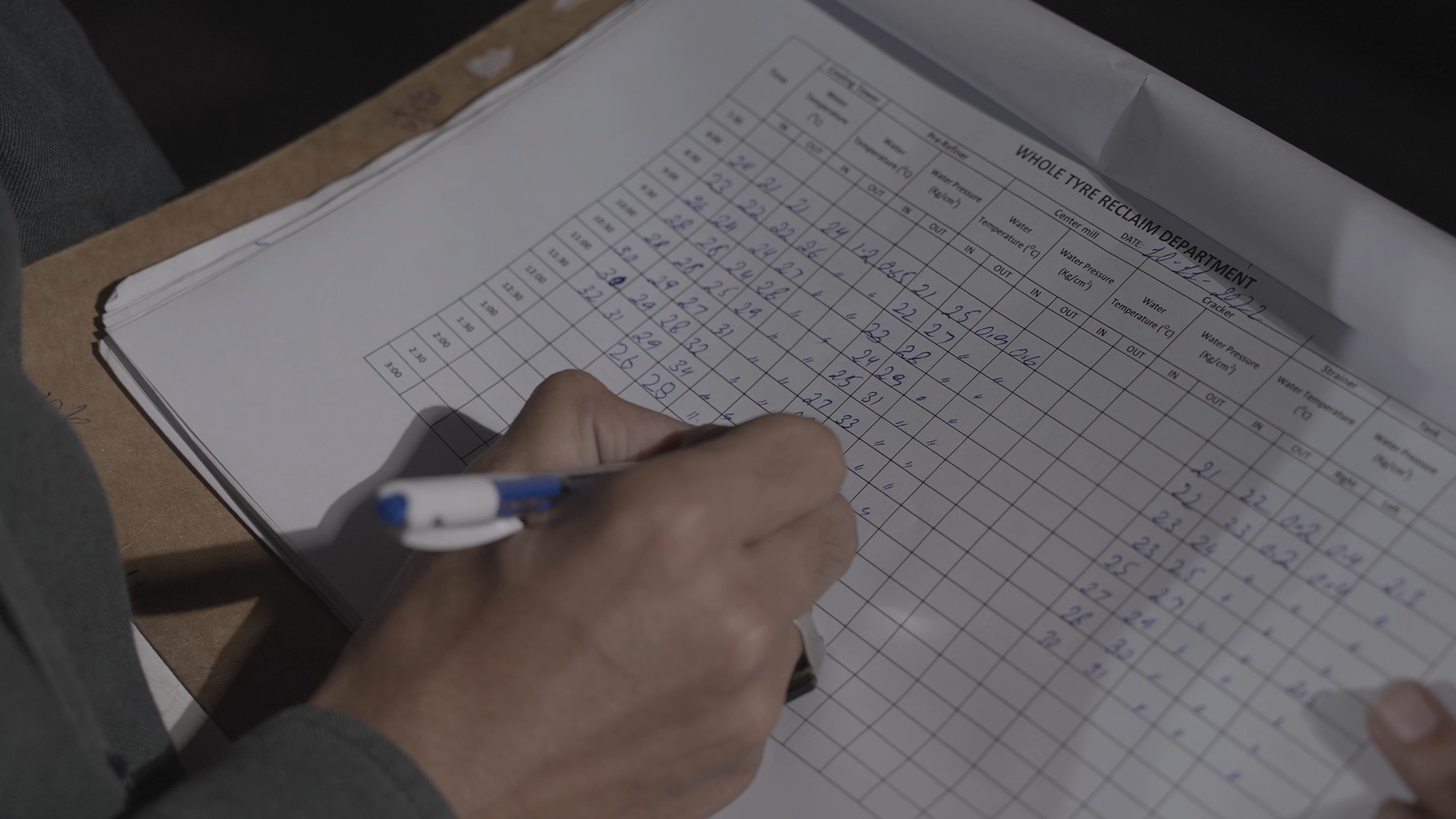

Once the process of receiving, sorting and washing of raw material has passed through various inspection stages, the production process starts. Straining of material through multiple sieves further boosts the confidence of end users. The production process is carefully managed and controlled using a robust QMS prescribed as per ISO 9001:2015 that is run by trained quality control and process engineers.